| Research Article | ||

Open Vet. J.. 2024; 14(12): 3599-3613 Open Veterinary Journal, (2024), Vol. 14(12): 3599-3613 Research Article Feed wafers from fermented sugarcane tops and Tithonia diversifolia with added tapioca starch: Effects on physical quality and in-vitro parameters for ruminant feedNovirman Jamarun1, Zaitul Ikhlas2*, Mardiati Zain1, Windu Negara3, Roni Pazla1 and Gusri Yanti41The Department of Nutritive Science and Animal Feed Technology, Faculty of Animal Science, Universitas Andalas, Padang, Indonesia 2Graduate Program, Faculty of Animal Science, Universitas Andalas, Padang, Indonesia 3Livestock Research Centre, The National Research and Innovation Agency, Cibinong Science Center, Cibinong, Indonesia 4Faculty of Social, Science and Education, Prima Nusantara Bukittinggi University, Kota Bukittinggi, Indonesia *Corresponding Author: Zaitul Ikhlas. Graduate Program, Faculty of Animal Science, Universitas Andalas, Padang, West Sumatra, Indonesia. Email: zaitul [at] student.unand.ac.id Submitted: 13/10/2024 Accepted: 26/11/2024 Published: 31/12/2024 © 2024 Open Veterinary Journal

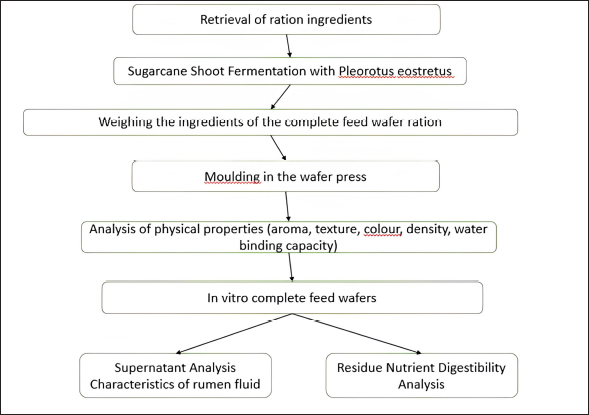

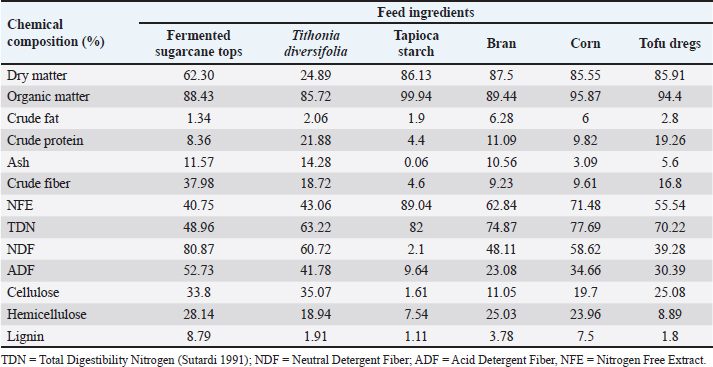

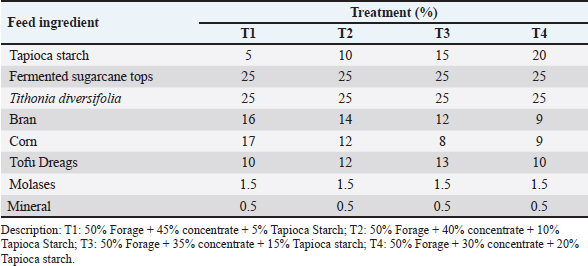

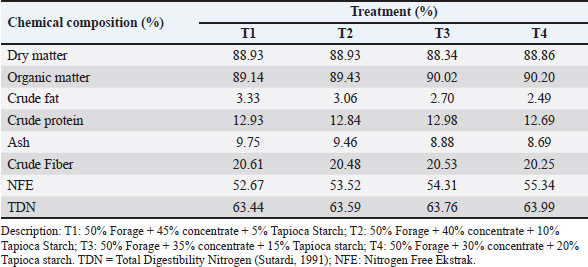

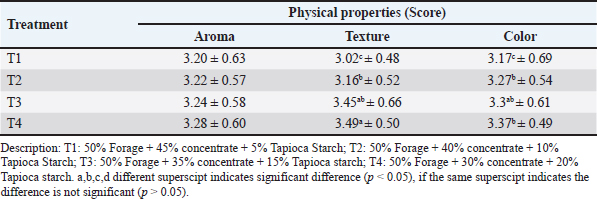

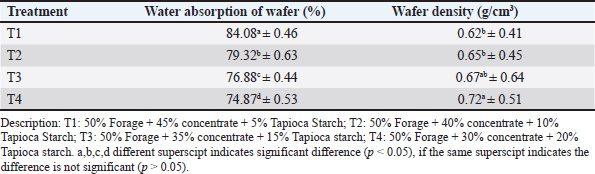

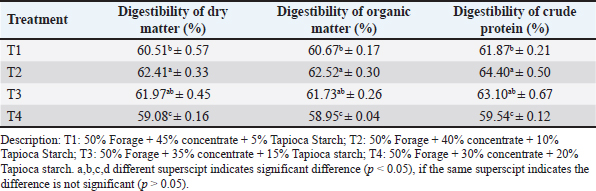

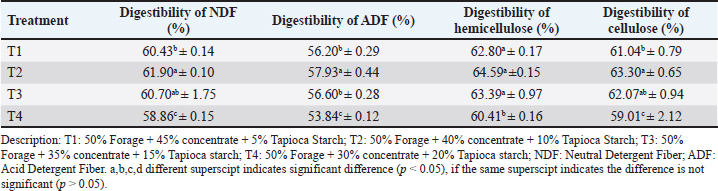

AbstractBackground: Alternative feeds for ruminants that can be explored are sugarcane tops as a source of crude fiber and tithonia as a source of protein. Long droughts and direct use of these components may not meet nutritional standards. Processing technologies such as wafer production, using tapioca starch as an adhesive, can improve feed durability, storage, and nutritional consistency. The addition of tapioca starch in ruminants’ feed should be considered, as its high starch content may affect overall feed digestibility. Aim: This research aims to assess at knowing the impact of the use of tapioca starch as an adhesive on complete feed wafers based on fermented sugarcane tops and tithonia to produce sturdy physical quality of wafers and increase in vitro digestibility of nutrients. Methods: The experiment used a group randomized design with four treatments, consisting of 5% tapioca starch in the ration (T1), 10% tapioca starch in the ration (T2), 15% tapioca starch in the ration (T3), 20% tapioca starch in the ration (T4), and five groups as replicates. The parameters included the physical properties of wafers (aroma, texture, color, water binding capacity, and density), in vitro digestibility of nutrients, volatile fatty acids production, NH3, pH, methane gas production, and total gas production. Results: The results indicated that the use of tapioca starch had a non-significant effect (p > 0.05) on color and a significant effect (p < 0.05) on aroma and texture. Digestibility of nutrients, rumen fluid characteristics, and total gas and methane gas production were significant (p < 0.05). Has a firm, dense texture (not easily broken), a distinctive aroma of wafers, and a stable rumen pH of 6.96 in the T2 treatment made effective rumen conditions indicated by dry matter digestibility of 62.41%, organic matter digestibility of 62.52%, and protein digestibility of 64.40%. Conclusion: The research concludes that in the T2 treatment, the addition of 10% tapioca flour as an adhesive and energy source in a complete feed wafer ration based on fermented sugarcane tops and tithonia being the best treatment for physical quality, and nutrient digestibility. Keywords: Digestibility, Fermented sugarcane tops, Physical properties, Tithonia diversifolia, Wafer. IntroductionThe need for quality feed for ruminants continues to increase along with the development of the livestock sector. One of the main obstacles in providing ruminant feed is the availability of high-quality, affordable, and easily obtainable feed ingredients throughout the year. Therefore, the use of alternative feed ingredients derived from local sources, such as sugarcane tops and Tithonia diversifolia, is a solution worth considering (Ikhlas et al., 2023). Sugarcane tops are an abundant agricultural waste in sugarcane-producing areas. Sugarcane top starch has nutritional contents such as dry matter 89.35%; organic matter 91.57%; crude protein 5.68%; Acid Detergent Fiber (ADF) 45.71%; Cellulose 28.21%; Lignin 15.05%; Neutral Detergent Fiber (NDF) 57.13%; and Hemicellulose 11.41% (Pazla et al., 2021a). Despite the high crude fiber content, the potential of sugarcane tops as animal feed is still limited due to the high lignin content (Ensminger et al., 1990). To reduce lignin content by fermentation using Pleurotus oestreatus mushroom species, extracellular oxide enzymes obtained in P. oestreatus mushrooms will degrade lignin, including lignin peroxidase and manganese peroxidase for 28 days can reduce lignin content by 23.25% (Pazla et al., 2021a). The fermentation process will increase the nutrient content and improve the fiber quality of sugarcane tops, making it easier for ruminants to digest. On the other hand, T. diversifolia, also known as paitan, has a fairly high protein content and great potential as a feed source. The nutritional content of tithonia includes crude protein 22.98%, organic matter 25.57%, NDF 61.12%, Crude fiber 18.17%, ADF 40.15%, Cellulose 34.18%, and lignin 4.57% (Jamarun et al., 2018). Tithonia is utilized as an alternative source of protein feed for ruminants (Pazla et al., 2021b; Jamarun et al., 2023). The combination of fermented sugarcane tops and Tithonia is expected to create feed with a balance between energy and protein needed for ruminant growth. Usually, fermented sugarcane tops and tithonia are given directly to livestock so it is feared that nutritional adequacy is still below the standard nutritional needs of ruminants (Pazla et al., 2022; Pazla et al., 2023; Jamarun et al., 2024; Pazla et al., 2024). The long dry season makes forage easily damaged due to high water content (Solihin and Sutrisna, 2015). Therefore, processing technology is needed to increase durability and maintain the nutritional adequacy of livestock, namely wafers. The wafer is one of the feed processing technologies that uses pressing and heating techniques so that the material becomes strong and sturdy. The advantages of processing feed into wafers include increasing density, reducing storage space, reducing transportation costs, making it easier to control, monitor, and regulate livestock feed intake, consistent and guaranteed nutrient content, breaking down dust and respiratory problems in ruminants (Sabri et al., 2017). Tapioca starch, which is a source of energy from carbohydrates, has the potential to be used as a binder in the manufacture of animal feed wafers (Yu et al., 2020; Cong et al., 2022). Usage of 5% tapioca in papaya leaf wafers with silage and ammoniation processing techniques provides the best physical quality of dark brown color, firm and unbreakable texture, and fragrant aroma typical of wafers, density of 0.47 g/cm2, water absorption of 46.40% (Harahap et al., 2021). However, the addition of tapioca starch in feed must be considered, as its high starch content can affect overall feed digestibility. A sturdy and durable wafer is one of the references to see the physical quality of the wafer, one of which must be considered is the adhesive used. Therefore, in vitro research is essential to evaluate the impact of using tapioca starch in fermented sugarcane tops and Tithonia-based diets on the physical properties of feed wafers and nutrient digestibility by ruminants. Thus, this study aims to assess the use of tapioca starch as an adhesive and energy source in complete feed wafers based on fermented sugarcane tops and T. diversifolia on physical properties and in vitro nutrient digestibility, which is expected to contribute to improving the quality of ruminant feed. Material and MethodsResearch flow chartThe research flow chart can be seen in Figure 1. Research materialThe ingredients used in the experiment were sugarcane tops taken from sugarcane plantation herds in Puncak Lawang agam district, T. diversifolia taken from Padang Panjang, Pleurotus ostreatus purchased in Padang city, tapioca starch, Concentrates (Corn, bran, tofu pulp, molasses), rumen fluid. As well as materials for proximate analysis, van soest, and in vitro assay. The tools used in this research are an animal feed wafer molding machine, analytical balance (AS220 R2 made in Polandia), coarse scales (Fujitsu FSR – B 620 made in Indonesia), shaker incubator (Eppendorf™ Innova™ 40R Incubator Shaker made in Swedia), oven (Un 30 Memmert Universal Oven made in Germany), centrifuge (Top Table Centrifuge Gemmy PLC 05 Model PLC-05 made in Taiwan), and a set of tools for in vitro, proximate analysis, van soest analysis, analysis of physical properties of wafers, analysis of rumen fluid characteristics, protozoa population, microbial protein synthesis, total gas production, and methane gas. Research designThis research used a group randomized design with four treatments and five groups as replicates. The used Treatments consisted of the following: T1: 50% Forage + 45% concentrate + 5% tapioca starch T2: 50% forage + 40% concentrate + 10% tapioca starch T3: 50% Forage + 35% concentrate + 15% tapioca starch T4: 50% Forage + 30% concentrate + 20% tapioca starch Table 1 shows the nutritional value of each component that composed the feed wafer ration. Table 2 displays the treatment ration composition. Table 3 displays the treatment’s nutritional content. Test parametersThe parameters that were analyzed in this study consisted of: 1. Physical properties of wafers including wafer aroma, wafer texture, wafer color, water binding capacity, and density. 2. In vitro digestibility of dry matter, organic matter, crude protein, ADF, NDF, Cellulose, and Hemicellulose. 3. Rumen fluid characteristics include rumen pH, total gas production, and NH3 production. 4. Total gas and methane gas production.

Fig. 1. Research flow chart. Table 1. Nutrient content of complete feed wafer rations.

Research procedureSugarcane tops fermentation The method used in sugarcane tops fermentation is (Pazla et al., 2021a). The Puncak Lawang sugarcane plantation area in the Agam district of West Sumatra was the source of the sugarcane tops collected. After being collected, the sugarcane tops are separated from their stems and air dried in the sun. Once the sugarcane tops were dried, they were placed into the chopping machine. After all the chopped sugarcane tops were weighed as much as 5 kg and then spread evenly on a tarpaulin, P. ostreatus mould was added 10% of the weight of the sugarcane tops. It was then wrapped in plastic, compressed in an anerobic environment, knotted, and incubated for 21 days. The sugarcane tops were dried and mashed after the incubation period. Table 2. Ration composition of complete feed wafer rations.

Table 3. Ration nutrient content of complete feed wafer treatment.

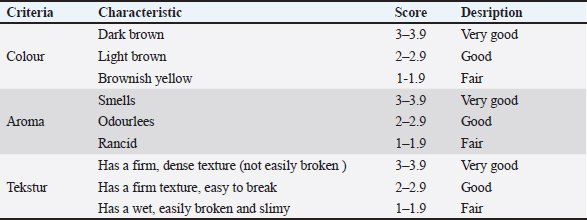

Table 4. Wafer characteristics assessment criteria (Solihin and Sutrisna, 2015).

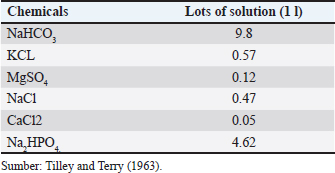

Preparation of complete feed wafers Tithonia and fermented sugarcane tops were dried at 60°C oven for 24 hours, and mashed. Concentrates consist of bran, tofu pulp, corn, molasses, minerals, salt, and tapioca starch. Weighed according to each treatment listed in Table 2. Mix all the ingredients that have been weighed into one container, add hot water as much as 1/5 of the weight of the ration, put it into a wafer printer, and press it, until the complete feed wafer is ready to use. Table 5. Composition of Mc Dougalls solution.

Determination of texture, aroma, and color of wafers The method used in the determination of texture, aroma, and color of wafers is (Solihin and Sutrisna, 2015), assessment of the physical properties of wafers (color, texture, and aroma) was based on treatment samples, with each treatment consisting of 20 testers. Observations of physical properties are carried out by making scores for each wafer criterion, which can be seen in Table 4. Wafer water absorption The method used in wafer water absorption (Trisyulianti et al., 2003), wafer water absorption was derived from measuring the weight of wafers before and after being soaked with water for 5 minutes. The percentage of water absorption was obtained by the equation 1:

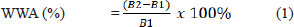

where, WWA=Wafer water absorption B1=Initial weight (g) B2=Final weight (g). Wafer density In the method used in wafer density (Trisyulianti et al., 2003), The wafer density value was calculated by equation 2 :

where, K=Wafer density (g/cm3) W=Weight of test sample (g) P=Length of test sample (cm) L=Width of the test sample (cm) T=Thickness of test sample (cm). In vitro assay preparationMcDougalls solution The composition for making McDougall’s solution as a buffer solution can be seen in Table 5. Reagents were diluted into distilled water and prepared 1 day before the in vitro assay and then put into a shaker water bath at a stable temperature of 39°C and kept supplied with CO2 gas for 30–60 seconds to maintain an anaerobic condition. Rumen fluid collection Rumen fluid was collected in the morning at the slaughterhouse. Ingesta was squeezed into a thermos with a temperature of 39°C with CO2 flowing. It is intended that the temperature is maintained and microbial environmental conditions remain anaerobic. The rumen fluid was then filtered with gauze with the amount needed for mixing with Mc Dougalls solution. In-vitro digestibility evaluation (Suningsih et al., 2017) The samples were weighed (2.5 g) and placed into a 250 ml Erlenmeyer tube. The buffer solution (Mc Dougall’s solution) (200 ml) and rumen fluid (50 ml) were added (4:1) to each Erlenmeyer tube. CO2 gas was flowed for 30–60 seconds to the conditions became anaerobic. The tubes were covered with a ventilated rubber lid to remove the gas and placed into a shaker water bath at 39°C, and incubated for 48 hours. The tubes were removed after 48 hours and placed in a basin containing ice to stop the microbial activity. Samples were centrifuged for 15 minutes at 3,000 rpm to separate the supernatant from the residue. The supernatant was taken to continue the analysis of volatile fatty acids (VFAs) and NH3. The residue was filtered with Whatman filter paper no. 41 and dried in an oven (60°C). Rumen fluid and buffer were used without samples as a blank. Nutrient digestibility Proximate digestibility (digestibility of dry matter, organic matter, and crude protein) (AOAC, 2005) and the digestibility of the fiber fraction digestibility (ADF, NDF, cellulose, and hemicellulose digestibility) (Van Soest et al., 1991). Equation:

where DMD is Digestibility of Dry Matter, SW is Sample Weight, DMD is Dry Matter Sample, RW is Residual Weight, DMR is Dry Matter Residual, DOM is Digestibility of Organic Matter, OMS is organic Matter sample, OMR is Organik Matter Residual, DCP is Digestibility of Crude Fiber, CPS is Crude protein sample, NDFS is NDF sample, NDFD is NDF digestibility, NDFR is NDF Residu, ADFD is ADF Digestibility, ADFS is ADF Sample, ADFR is ADF Residu, CelD is Celulosa Digestibility, CelS is Celullose sample, CelR is Celullose Residu, HemcD is Hemicelullosa digestibility, HemcS is Hemicellulose sample, HemcR is Hemicelullosa is Residu. Table 6. Physical properties (aroma, texture, and color) (Score).

Table 7. Water absorption of wafer and wafer density.

Table 8. In vitro digestibility of dry matter, organic matter, and crude protein.

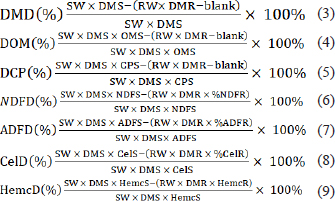

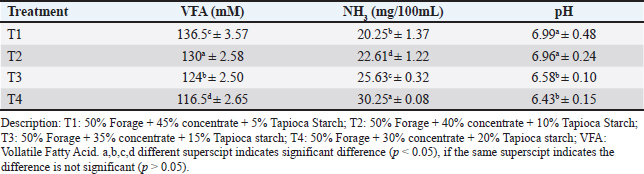

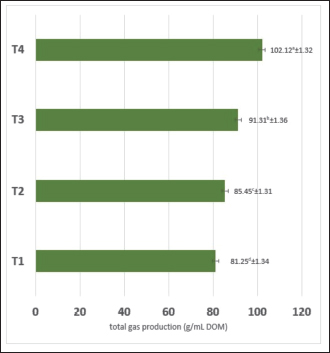

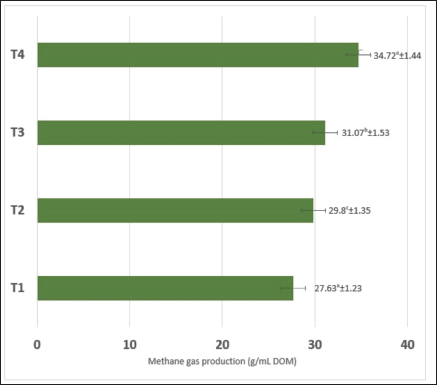

Total gas and methane gas production In the method used in total gas and methane gas production (Fievez et al., 2003), Gas measurements were taken every 12, 24, 36, and 48 hours to prevent gas production from exploding. After measuring the gas volume and withdrawing the gas with a syringe after the incubation, the lower end of the syringe was attached to the lower end of another syringe that had 4.0 ml of NaOH (10 M). To prevent gas escape, NaOH (10 M) was thereafter added from the latter to the contents that were being incubated. CO2 can be absorbed by mixing the contents with NaOH; the gas that remains in the syringe is regarded as CH4. Furthermore, methane gas and total gas were calculated by summing the volume of total gas and methane gas read on the syringe measured during fermentation. Statistical analysis Analysis of variance was used to analyze the research data. The Duncan’s Multiple Range Test was used to compare treatment differences using IBM SPSS Statistics, USA’s version 21.0 of the SPSS program. Ethical approval Not needed for this study. ResultsPhysical properties of wafers (aroma, color, and texture)In Table 6, it can be seen that the treatment has a significant effect on the physical properties of wafer color and wafer texture (p < 0.05). While the physical properties of wafer aroma did not have a significant effect (p > 0.05). The color of the complete feed wafer was evaluated by 20 panelists, with scores ranging from 3.17 to 3.37 (dark brown). The highest score was recorded in treatment T4 (3.37), while the lowest was in treatment T1 (3.17). The Aroma of the complete feed wafer was also assessed by 20 panelists, with scores ranging between 3.1 and 3.4 (characteristic of wafer feed). The highest score was observed in treatment T4 (3.4), and the lowest was in treatment T1 (3.1). The texture of the complete feed wafer was evaluated by 20 panelists, with scores ranging from 3.02 to 3.49 (Firm, dense texture, not easily broken). The highest score was found in treatment T4 (3.49), while the lowest was in treatment T1 (3.02). Wafer densityTable 7 shows that the concentration of tapioca starch in complete feed wafers has a significant impact on wafer density (p < 0.05). Wafer density is one of the indicators of the wafer’s quality. The highest density was found in treatment T4 with a value of 0.72 g/cm3. Meanwhile, one of the lowest values was T1 with a value of 0.62 g/cm3. The DMRT test revealed that while T1, T2, and T3 were not substantially different (p > 0.05), T1 and T4 were considerably different (p < 0.05). T3 and T2 treatments did not vary substantially (p > 0.05), whereas T4 and T2 treatments did (p < 0.05). T4 and T3 treatments differed considerably (p < 0.05). Water binding capacity of wafersTable 7 shows that the use of different tapioca starch in complete feed wafers had a significant effect on water binding capacity (p < 0.05). Treatment T1 was significantly different (p < 0.05) from treatments T2, T3, and T4. T2 treatment was significantly different (p < 0.05) with T3 and T4 treatments. However, the T3 treatment was not significantly different (p > 0.05) with T4. Water absorption in this study ranged from 74.87% to 84.08%. Dry matter, organic matter, and crude protein digestibilityTable 8 demonstrates that the digestibility of dry matter, organic matter, and crude protein was significantly affected (p < 0.05) by the treatment. The T2 treatment had the highest dry matter digestibility (62.41%), whereas the T4 treatment had the lowest dry matter digestibility (59.08%). With a score of 62.52%, the T2 treatment had the highest organic matter digestibility, whereas the T4 treatment had the lowest, at 58.95%. At 64.40%, the T2 treatment had the highest crude protein digestibility, whereas the T4 treatment had the lowest, at 59.54%. Dry matter, organic matter, and crude protein digestibility got the best digestibility value in the T2 treatment. Digestibility of ADF, NDF, cellulose, and hemicelluloseTable 9 demonstrates that the treatment had a substantial impact (p < 0.05) on the cellulose, hemicellulose, ADF, and NDF digestibility. With a score of 57.93%, the T2 treatment had the highest ADF digestibility, whereas the T4 treatment had the lowest ADF digestibility (53.84%). With a score of 61.90%, the T2 treatment had the highest NDF digestibility, while the T4 treatment had the lowest, at 58.86%. At 63.30%, the T2 treatment had the maximum cellulose digestibility, while the T4 treatment had the lowest, at 59.01%. It was discovered that the T2 treatment had the highest hemicellulose digestibility, measuring 64.59%, while the T4 treatment had the lowest, measuring 60.41%. Treatment T2 had the highest van Soest digestibility. Characteristics of rumen fluid (pH, VFA, and NH3)Table 10 shows that the treatment had a significant effect (p < 0.05) on the pH value of the rumen fluid. The pH value in this study ranged from 6.43 to 6.99. The highest pH value was found in treatment T1 with a value of 6.99, while the lowest pH value was found in T4 with a value of 6.43. The VFA content and NH3 concentration had a significant effect (p < 0.05) among the treatment. The highest VFA content was found in treatment T4 with a value of 136.5 mM, while the lowest VFA content was found in treatment T1 with a value of 116.5 mM. The NH3 concentration ranged from 20.25 to 30.05 mg/100 ml. The highest NH3 concentration was found in treatment T4 (30.05 mg/100 ml), while the lowest was found in treatment T1 with a value of 20.25 mg/100 ml. Total gas production and methane gasFigures 2 and 3 show that the treatment had a significant effect (p < 0.05) on total gas production and methane gas production. Total gas production ranged from 81.25 to 102.12 ml/g OM digested. The highest total gas production was found in treatment T4 with a production of 102.12 ml/g OM digested, and the lowest total gas production was found in treatment T2 with a production of 81.25 ml/g OM digested. The highest methane gas production was found in the T4 treatment with a production of 34.72 ml/g OM digested, while the lowest one was found in the T2 treatment with a production of 27.63 ml/g OM digested. Table 9. Digestible of NDF, digestible of ADF, digestible of hemicellulose, digestible of cellulose.

Table 10. VFA concentration, NH3 concentration, and rumen pH.

DiscussionPhysical properties of wafers (Aroma, color, and texture)Wafer aroma The aroma from the fermentation process of sugarcane tops using Pleorotus eostretus mould has the ability to convert various compounds contained in the media into other simpler compounds, providing a distinctive flavor and aroma of fermentation in feed (Candrasari et al., 2019). The aroma of wafers comes from the heating process of the ingredients that make up the wafer ration consisting of fermented sugarcane tops, tithonia, tofu pulp, bran, corn, and molasses containing starch, as well as adhesives that strengthen the aroma of wafer origin, which is typical of caramel. This is in accordance with the opinion of (Wati et al., 2020) that in addition to the heating of feed ingredients, molasses, and tapioca starch cause a fragrant aroma due to the presence of sugar content, so the aroma caused is generally fragrant like caramel. Wafer colour The results showed that wafers using 20% tapioca starch gave a higher average color with a score of 3.37 compared to other treatments, but the organoleptic assessment produced the same color, namely dark brown. This is thought to be because in the T4 treatment the use of tapioca starch is more than the other treatments, tapioca starch contains high carbohydrates, so when heated it will undergo a browning process (maillard reaction) (Nimitkeatkai et al., 2022). The higher concentration of tapioca starch in the wafer ratio will cause a dark brown color change. According to Winarno (1992), caramelization occurs when a sucrose solution is evaporated until all the water has evaporated. If heating is continued, the liquid that exists does not consist of water but is a melted sucrose liquid. Wafer texture Treatment T4 using 20% tapioca starch presented the highest wafer texture with a score of 3.49. This occurs because of the high starch content in the T4 treatment, the starch heated in the wafer printing machine will form a gel which causes the wafer texture to be dense and not easily destroyed. A compact texture will increase feed efficiency because the feed will not be scattered (Retnani et al., 2020). Tapioca starch when added to water in the ration will increase the viscosity of the mixture, thus obtaining stronger and sturdier wafers. Tapioca starch as an adhesive also has the ability to fill the gaps between particles in the wafer, so as to improve the structure of the wafer. Increasing the concentration of tapioca starch strengthens the structure, making the texture tighter and harder (Ikhlas et al., 2024). The texture of the wafers in each organoleptic treatment is still fairly the same. The type and percentage of adhesive used in wafers can affect the density of the wafer texture (Syahri et al., 2018). Textures that are too firm will also affect water absorption, the lower the water absorption produced by the wafer, the more it will affect palatability for ruminants. According to Wong et al. (2015), a texture that is too firm reduces the pore space for water absorption. Wafer density The results showed that the addition of tapioca starch with different concentrations in the wafer ratio gave a significantly different effect on wafer density. In Table 7, the highest density is found in the T4 treatment (20% tapioca starch) with a value of 0.72 g/cm3, this occurs because of the high starch content in the T4 treatment when heated and mixed with the constituent ingredients of the wafer and added water will form a gel that can increase cohesion between ingredients in the wafer. According to Harahap et al. (2021), the higher the concentration of tapioca used in the wafer ration, the higher the density of the wafer.

Fig. 2. Total gas production (g/ml DOM). T1: 50% Forage + 45% concentrate + 5% Tapioca Starch; T2: 50% Forage + 40% concentrate + 10% Tapioca Starch; T3: 50% Forage + 35% concentrate + 15% Tapioca starch; T4: 50% Forage + 30% concentrate + 20% Tapioca starch; DOM: digestibility organic Matter. Higher concentrations of tapioca starch tend to produce wafers with a tighter structure because starch fills the gaps between particles of other ingredients. This process reduces the pores in the wafer, thus increasing its density. Wafers that are too dense are less optimal for consumption by ruminants, as they will affect the digestibility and palatability of ruminants (Retnani et al., 2020). Water absorbency Water absorption is closely related to wafer density. It can be seen in Table 7 that the T1 treatment gets high water absorption, this happens because the density in the T1 treatment is low, so the pores in the wafer are more spaced than in other treatments, causing a lot of water to be absorbed in the higher water in the wafer. The higher the wafer density value, the lower the wafer water absorption value (Syahri et al., 2018), low water absorption will make it difficult for the destruction of wafers by saliva when consumed by ruminants, but too high water absorption can also cause wafers not to last long in storage (Krisnan and Ginting, 2009). Digestibility of dry matter, organic matter, and crude proteinDry matter digestibility This happens because tapioca starch not only functions as an adhesive but also as a source of energy for ruminants. Tapioca starch is a carbohydrate that has a simple structure, so it is easily digested to be used as energy. According to Wanapat et al. (2013), using tapioca starch containing simple carbohydrates as an energy source for ruminants can help the efficiency of absorption of nutrients from feed. There was a decrease in digestibility in the treatment (T3 and T4), a decrease in dry matter digestibility occurred because too much tapioca was given which could affect the microbial composition in the rumen of ruminants. Research by Utomo et al. (2013) states that changes in the composition of feed in the ration can encourage the growth of certain fermentation microbes in the rumen, which are not beneficial for ruminants. More beneficial bacteria usually help in the fermentation process in the rumen and can be suppressed by the growth of other bacteria due to excessive use of tapioca starch, thus reducing dry matter digestibility (Rahmawati et al., 2021). Research (Sandi et al., 2015) said that the use of tapioca flour as much as 5% in the ration of wafer animal feed got a dry matter digestibility of 65.41%, the digestibility of dry matter obtained in the study of 62.41% is lower than the research Sandi. This is probably because the ingredients used in the ration are different. Digestibility of organic matter The digestibility of organic matter is one of the indicators of the efficiency of nutrient use by ruminants. In this study, it can be seen in Table 8 that the highest digestibility of organic matter is found in the T2 treatment (10% tapioca starch) with a value of 62.52%. This high digestibility occurs due to the nature of tapioca starch as a source of easily digestible carbohydrates, which plays a role in increasing the digestibility of organic matter in complete feed wafer rations (Lestari, 2019; Istiadi et al., 2020). In tapioca, there are glucose-type carbohydrates that are important for livestock as a source of energy for their bodies (Naytili et al., 2022). This is in accordance with research by Harahap et al. (2021) which states that carbohydrate-based adhesives such as tapioca can produce an optimal physical structure of feed to increase the digestibility of organic matter. The use of tapioca starch in the ration with the right amount can help the optimal energy balance which is useful for maintaining good digestibility (Asis, 2021; Ardigurnita, 2023). The digestibility of organic matter in the T2 treatment with a value of 62.52%, compared to research (Sandi et al., 2015) that the addition of 5% tapioca flour in the wafer ration obtained a digestibility of organic matter of 60.89%, this proves that this study is better than Sandi’s research in terms of digestibility of organic matter. Crude protein digestibility This increase can occur because the carbohydrates contained in tapioca starch have a role in increasing microbial activity in the rumen. Increasing microbial activity in the rumen can play a role in the process of digesting crude protein more optimally (Riswandi et al., 2017). Carbohydrates which are the main component in tapioca starch can help in providing good fermentation, which can help in the absorption of protein efficiently (Boangmanalu et al., 2016; Pramono et al., 2022).

Fig. 3. Methane gas production (g/ml DOM). T1: 50% Forage + 45% concentrate + 5% Tapioca Starch; T2: 50% Forage + 40% concentrate + 10% Tapioca Starch; T3: 50% Forage + 35% concentrate + 15% Tapioca starch; T4: 50% Forage + 30% concentrate + 20% Tapioca starch; DOM: digestibility organic matter. Crude protein digestibility in treatments T3 and T4 with the addition of 15% tapioca starch and 20% tapioca starch caused a decrease in digestibility. This decrease proves that the optimal use of tapioca starch in complete feed wafers is 10% tapioca starch. The decrease in crude protein digestibility is due to too much tapioca starch causing acidosis in the rumen fluid. Acidosis causes a decrease in the effectiveness of rumen microbes, especially proteolytic bacteria that play a role in digesting crude protein (Riswandi et al., 2015). Research by Astuti et al. (2020) found that fermented corn cobs added with 10% tapioca flour got a crude protein digestibility of 51.37%, compared to this study the digestibility of crude protein with the addition of 10% tapioca flour reached 64.40%. This may be due to the different ration composition so that in this study the digestibility increased. Digestibility of ADF, NDF, cellulose, and hemicelluloseADF digestibility It can be seen in Table 9 that the highest crude protein digestibility is found in T2 (addition of 10% tapioca starch). This can occur because tapioca starch has a role as an effective source of energy in animal feed, starch contained in tapioca starch plays a role in increasing rumen microbial activity. The presence of balanced starch in the rumen can create optimal conditions for microbial activity, so that optimal conditions can increase ADF digestibility (Harmon and Swanson, 2020; Chen et al., 2022). Tapioca starch contains starch that can assist and improve fermentation in the rumen, which helps facilitate the digestion of fiber (Harmon and Swanson, 2020). In the T3 (15% tapioca starch) and T4 (20% tapioca starch) treatments, ADF digestibility decreased. This proves that the use of tapioca starch above 10% starts to have a negative impact on ADF digestibility. The use of excessive amounts of tapioca causes carbohydrates to not be digested efficiently by ruminants, leading to suboptimal nutrient absorption (Zhao et al., 2018; Li et al., 2020). The balance in the rumen can be disturbed due to the excessive use of starch, potentially reducing fiber digestibility (Vuuren et al., 2010). Digestibility of NDF The results showed that the T2 treatment (using 10% tapioca starch) gave the highest NDF digestibility with a value of 61.90%. This occurs because the role of tapioca starch is not only as an adhesive but also as an effective source of energy, the starch contained in tapioca starch helps to keep the rumen pH stable and provides a substrate that is easily digested. The starch contained in tapioca starch contributes to fiber digestion by supporting cellulolytic and hemicellulolytic activities, which have important roles in the fiber digestion process (Zhao et al., 2018). The activity of fiber-breaking microorganisms works optimally when the rumen pH is stable, so fiber will be more easily digested by cellulolytic and hemicellulolytic bacteria (Retnani et al., 2020; Kowel et al., 2022). There was a decrease in NDF digestibility in treatments T3 (addition of 15% tapioca starch) and T4 (addition of 20% tapioca starch), the use of tapioca starch above 10% has a negative impact on ruminants. The decrease in NDF digestibility occurs due to excessive starch content in tapioca starch. This is because starch fermentation will produce gas, in the form of CO2 and methane. Intensive starch fermentation can increase the osmotic pressure in the rumen, causing osmotic stress on microbes and slowing down the enzymatic activity needed to digest fiber. High gas production can accelerate the transit of food through digestion. This decreases fiber retention time in the rumen, resulting in less optimal fiber digestion (Calsamiglia et al., 2012). Cellulose digestibility In Table 9, it can be seen that the highest cellulose digestibility is found in the T2 treatment (10% tapioca starch) with a value of 63.30%, while the T1 treatment (5% tapioca starch) has not been able to provide the best cellulose digestibility in this study. The high cellulose digestibility in the T2 treatment was due to tapioca starch being an easily digestible energy source, which contributes to the balance of fermentation in the rumen, this balance will increase the activity of cellulolytic microbes that play a role in fiber digestion (Elihasridas et al., 2023). Tapioca starch is a source of soluble carbohydrates, which can serve to increase the population of cellulolytic bacteria in the rumen, thus supporting the cellulose fermentation process. Increased cellulolytic bacterial activity will increase cellulose digestibility, which is very important for feed efficiency in ruminants (Elihasridas et al., 2023). The use of tapioca starch at concentrations of more than 10% as in the T3 and T4 treatments decreased cellulose digestibility. The decrease in cellulose digestibility is due to the dominant amylolytic bacteria due to large amounts of starch, which can reduce the number of cellulolytic microbes needed to digest crude fiber, especially cellulose (Horstmann et al., 2016). Hemicellulose digestibility The high digestibility of hemicellulose in the addition of 10% tapioca starch occurs because tapioca starch serves as a source of energy for rumen microbes and can accelerate the fermentation process. When starch is fermented, it provides energy that is used by rumen microbes to degrade fibers including hemicellulose, as microbes become more active in breaking down complex fibers into simpler components (Elihasridas et al., 2023). However, treatments T3 (15% tapioca starch) and T4 (20% tapioca starch) significantly decreased hemicellulose digestibility. This is due to the excessive use of tapioca starch so that amylolytic microbes become dominant. The dominance of amylolytic microbes will reduce the pH of the rumen so that it disturbs other microbial activities, such as hemicellulose. This research is in line with the explanation (Lestari et al., 2020) that a decrease in rumen pH can inhibit the growth and activity of hemicellulolytic bacteria needed for fiber digestion. Rumen fluid characteristics (pH, VFA, and NH3)Rumen pH In this study, the rumen pH data can be seen in Table 8, the highest rumen pH in this study was found in the T1 treatment (5% tapioca starch) with a value of 6.99, the rumen pH conditions in this treatment were very good so that rumen microbial activity became stable, having an effect on increasing feed digestibility. Stable rumen pH is very important to maintain the balance of microbes contained in the rumen, the optimal pH in the rumen ranges from 6.8 to 7.2 (Ihoeghian et al., 2022). In the T3 and T4 treatments, the rumen pH decreased significantly to 6.58 and 6.43. This decrease is caused by tapioca starch used in excessive amounts, the production of VFA will increase, which can reduce rumen pH. A decrease in rumen pH can disrupt microorganisms including cellulolytic, and proteolytic microbes that are important for fiber and protein digestion (Fiore et al., 2020; Sun et al., 2020). VFA concentration The results showed that the highest concentration of VFA was found in treatment T4, which is the use of 20% tapioca starch in complete feed wafers. Starch is a type of easily digestible carbohydrate contained in tapioca starch. Therefore, the more tapioca starch used, the higher the concentration of VFA produced. Fermentation of large amounts of starch contained in tapioca starch will result in increased VFA production in the rumen, especially propionate and butyrate (Rahman et al., 2020). Although increased VFA production is beneficial, it needs to be balanced, because the imbalance in the ration will reduce the overall efficiency of feed use (Penner, 2014; Silitonga et al., 2013). In addition, increasing VFA production also has an impact on decreasing rumen pH, which results in acidosis and disrupts the activity of microbes in charge of breaking down fiber such as cellulolytic microbes. The results showed that the use of excessive amounts of tapioca starch can increase propionate production and reduce the amount of acetate, thus disturbing the balance of fiber fermentation (Fitri et al., 2021). In the T2 treatment, the use of 10% tapioca starch showed a VFA concentration of 124.5 mM. The T2 treatment can create balanced conditions in the rumen so that microorganisms such as cellulolytics and amylolytics, cellulolytics digest crude fiber, while amylolytic bacteria digest starch well (Rahman et al., 2020). Starch from tapioca starch can increase the proportion of propionate, but does not disturb the balance of acetate production which plays an important role in fiber fermentation in the rumen. NH3 concentration The NH3 concentration in this study is still considered reasonable if consumed by livestock. Tapioca starch is a source of starch that is easily digested, so it can provide fast energy for rumen microbes. This energy is used by microbes to utilize nitrogen more effectively in the synthesis of NH3. The concentration of NH3 is influenced by rumen pH, if the rumen pH is stable then the use of NH3 efficiently by microbes (Pancasakti et al., 2022). The T2 treatment showed optimal conditions, where the VFA produced was high enough to support microbial energy, while NH3 was also utilized optimally. Amylolytic and cellulolytic microbes work in balance so that in the T2 treatment the pH obtained is stable and does not disturb fiber digestibility in the rumen. This study is in line with Rahman et al. (2020), which explains that the use of balanced carbohydrates can maintain amylolytic and cellulolytic microbial populations, thereby increasing fiber digestibility. In treatment T4 (20% tapioca starch), the NH3 concentration was highest with a value of 30.25 mg/100 ml. The increase in NH3 concentration in the T4 treatment was due to the high starch content in tapioca starch, fermented tapioca starch, will produce large amounts of energy, but is not balanced with the availability of sufficient protein to support NH3 synthesis. If there is not enough protein in the feed, the NH3 produced cannot be utilized properly by microbes, so the concentration of NH3 in the rumen increases (Suharnas, 2023; Cho et al., 2013). research by Oktarina (2014) explained that the use of tapioca flour resulted in NH3 production of 20.10 mg/100 ml, in line with this study which obtained NH3 production ranging from 20.25 to 30.25 mg/100 ml. Total gas and methane gas production The production of total gas and methane gas in the fermentation process is influenced by the amount and type of substrate used. This complete feed wafer research shows that there is a parallel relationship between total gas production and methane gas, the higher the total gas production, the higher the methane gas production, and vice versa (Rochyani et al., 2022). In treatment T1 (5% tapioca starch), the lowest total gas production (81.25 ml/g DOM) and methane gas (27.63 ml/g DOM) were obtained, this happened because the use of tapioca starch which was less than in other studies caused low total gas production and methane gas produced. Starch contained in tapioca starch will be digested by amylolytic microbes to produce VFA, CO2, and H2. H2 will be utilized by methanogens to produce methane (CH4) (Rahayu et al., 2018). It can be seen in Figures 2 and 3 that there is an increase in total gas production and methane gas in each treatment. It can be seen in Figures 2 and 3 that there is an increase in total gas production and methane gas in each treatment. This is evidenced by the high VFA content in the T4 treatment with the addition of 20% tapioca flour with a value of 136.5 mM, VFA is a carbohydrate fermentation that produces CO2 and H2 gas, the more CO2 and H2 gas produced, the higher the total gas production and methane gas obtained (Johnson and Johnson, 1995). High gas production does not fully indicate that fermentation occurs optimally, in this study the T4 treatment indicates a decrease in fiber digestibility and a decrease in rumen pH, which can inhibit the activity of cellulolytic microbes in digesting fiber (Calsamiglia et al., 2012). Research by Rochyani et al. (2022) found that the use of 20% tapioca flour was able to increase total gas production to 136.5 ml/g of digested organic matter, while methane gas production reached 27.63 ml/g of digested organic matter. The total gas production and methane gas in this study were lower than those in Rochyani’s study. ConclusionThis study showed that in treatment T2 the addition of 10% tapioca starch in the ration of complete feed wafers based on fermented sugarcane tops and tithonia provided good physical quality and optimal nutrient digestibility. It is hoped that this research will be an alternative during the long dry season. AcknowledgmentsThe authors would like to thank the research and community service Institution of Andalas University and the Faculty of Animal Science, University of Andalas. Conflict of interestThe authors declare that no conflicts of interest exist. FundingThis research was funded by the Institution of Research and Community Service of Andalas University, Indonesia (Main contract number No: 041/E5/PG. 02.00.PL/2024, derivative contract number 39/UN16.19/PT.01.03/PL/2024). Author’s contributionsZI and RP are in charge of drafting the script, and NJ and MZ improved and finished the manuscript. WN improved the language of the manuscript to make it better. GY analyzed the research data. All authors read and approved the final manuscript. Data availabilityAll data that support the findings of this study are available in the manuscript. ReferencesAOAC. 2005. Official methods of analysis, 18th ed. Arlington, VA: AOAC. Ardigurnita, F. 2023. Suplementasi air cucian beras dan belerang sebagai sumber mineral esensial alami untuk meningkatkan kecernaan pakan jerami padi amoniasi secara in vitro. Bull. App. Anim. Res. 5(1), 19–27. Asis, N. 2021. Pengaruh pemberian limbah sayur dalam ransum terhadap nilai kecernaan bahan kering, bahan organik dan protein itik lokal (anas sp). Janhus J. Ilmu Peternak. J. Anim. Husb. Sci. 6(1), 29. Astuti, T., Raharjo, I., and Sugoro, I. (2020). The effect of fermented corn cobs with the addition of tapioca flour on crude protein digestibility in ruminants. J. Anim. Feed Sci. Technol, 9(3), 123–129. Boangmanalu, R., Wahyuni, T. and Umar, S. 2016. Kecernaan bahan kering, bahan organik dan protein kasar ransum yang mengandung tepung limbah ikan gabus pasir (Butis amboinensis) sebagai substitusi tepung ikan pada broiler. J. Peternak. Integr. 4(3), 329–340. Calsamiglia, S., Cardozo, P.W., Ferret, A. and Bach, A. 2012. Changes in rumen microbial fermentation are due to a combined effect of type of diet and pH. J. Anim. Sci. 90(11), 4446–4455. Candrasari, D.P., Fitria, R. and Hindratiningrum, N. 2019. Pengaruh perlakuan amoniasi fermentasi (amofer) terhadap kualitas fisik janggel jagung. J. Ilm. Ilmu-Ilmu Peternak. 22(2),117–123. Chen, X., Fang, Y., Liu, T., Zhang, Y., Wang, M., Zhang, C. and Wu, S. 2022. Ruminal microbiota determines the high-fiber utilization of ruminants: evidence from the ruminal microbiota transplant. Microbiol. Spectr. 10(4), e0044622. Cho, S., Hwang, I. and Choi, N. 2013. Investigation of dietary lysophospholipid (lipidoltm) to improve nutrients availability of diet with in vitro rumen microbial fermentation test. J. Korean Soc. Grassl. Forage Sci. 33(3), 206–212. Cong, X., Li, X., Yang, G., Guo, D., He, T. and Li, J. 2022. Effects of dietary starch sources on pellet-processing characteristics, growth performance and caecal microflora of meat rabbits. J. Anim. Physiol. Anim. Nutr. 106(4), 888–898. Elihasridas, E., Erpomen, E. and Pazla, R. 2023. Substitusi rumput lapangan dengan jerami bengkuang terhadap kecernaan zat makanan secara in vitro. J. Peternak. Indones. (Indones. J. Anim. Sci.). 25(2), 246. Ensminger, M.E., Oldfield, J.E., & Heinemann, W.W. (1990). Feeds and Nutrition. The Ensminger Publishing Company, Clovis. Fievez, V., Dohme, F., Danneels, M., Raes, K. and Demeyer, D. 2003. Fish oils as potent rumen methane inhibitors and associated effects on rumen fermentation in vitro and in vivo. Anim. Feed Sci. Technol. 104(1–4), 41–58. Fiore, E., Faillace, V., Morgante, M., Armato, L. and Gianesella, M. 2020. A retrospective study on transabdominal ultrasound measurements of the rumen wall thickness to evaluate chronic rumen acidosis in beef cattle. BMC Vet. Res. 16(1), 337. Fitri, F., Bain, A. and Kurniawan, W. 2021. Uji kecernaan in vitro silase kombinasi sorgum (Sorghum bicolor) dan kalopo (Calopogonium mucunoides) dengan level asam laktat yang berbeda. J. Ilm. Peternak. Halu Oleo. 3(4), 415. Harahap, R.M., Harahap, A.E. and Febrina, D. 2021. Kualitas fisik wafer dengan penambahan berbagai level tepung tapioka serta tepung daun pepaya (Carica papaya L.) yang diolah dengan teknik berbeda. J. Triton. 12(2), 92–103. Harmon, D. and Swanson, K. 2020. Review: nutritional regulation of intestinal starch and protein assimilation in ruminants. Animal 14, 17–28. Horstmann, S.W., Foschia, M., Arendt, E.K., and Zannini, E. (2016). Nutritional therapy–Facing the gap between coeliac disease and gluten-free food. Int. J. Food Microbiol. 239, 113–124. Ihoeghian, N.A., Amenaghawon, A.N., Ajieh, M.U., Oshoma, C.E., Ogofure, A., Erhunmwunse, N.O. and Martin, A.D. 2022. Anaerobic co-digestion of cattle rumen content and food waste for biogas production: establishment of co-digestion ratios and kinetic studies. Bioresour. Technol. Rep. 18, 101033. Ikhlas, Z., Jamarun, N., Pazla, R., Welan, R., Yanti, G. and Sari, R.W.W. 2023. Blood metabolite status of peanut goats given basalt ration of sugar cane (Saccharum officinarum) and Titonia (Tithonia diversifolia) fermentation and addition of peel flour and avocado seeds in concentrate. In Developing modern livestock production in tropical countries. Eds., Adli, D.N., Pramujo, M. and Yekti, A.P.A. London, UK: CRC Press, pp: 68–71. Ikhlas, Z., Jamarun, N., Zain, M., Pazla, R., Yanti, G. and Utami, B.V. 2024. Physical properties of sugarcane (Saccharum officinarum) and tithonia (Tithonia diversifolia) shoot-based wafers with different adhesive types. Online J. Anim. Feed Res. 14(5), 287–294. Istiadi, M., Sutaryo, S. and Purnomoadi, A. 2020. Pengaruh substitusi by-product industri tapioka pada feses sapi perah sebagai substrat biogas terhadap nilai ph, produksi metan dan kecernaan bahan organik. J. Ilm. Peternak. Terpadu. 8(2), 53. Jamarun, N., Ikhlas, Z. and Sari, R.W.W. 2024. The effect of mangrove leaf (Rhizophora apiculata) based diet and fermented tithonia (Tithonia diversifolia) on the metabolite status of kacang goats. IOP Conf. Ser. Earth and Environ. Sci. 1341(1), 012067. Jamarun, N., Pazla, R., Yanti, G., Sari, R.W.W. and Ikhlas, Z. 2023. The impact of mangrove (Rhizophora apiculata) leaves hay and fermented Tithonia diversifolia on intake, nutrient digestibility and body weight gain of goat. Adv. Anim. Vet. Sci. 11(9), 1441–1450. Jamarun, N., Zain, M., Arief, P.R. and Pazla, R. 2018. Populations of rumen microbes and the in vitro digestibility of fermented oil palm fronds in combination with tithonia (Tithonia diversifolia) and elephant grass (Pennisetum purpureum). Pak. J. Nutr. 17(1), 39–45. Johnson, K.A. and Johnson, D.E. 1995. Methane emissions from cattle. J. Anim. Sci. 73(8), 2483–2492. Kowel, Y., Bagiu, A. and Londok, J. 2022. Kecernaan in vitro pakan broiler yang mengandung level asam laurat dan serat kasar berbeda. Zootec 42(2), 131. Krisnan, R. and Ginting, S.P. 2009. Penggunaan solid ex-decanter sebagai perekat pembuatan pakan komplit berbentuk pellet: evaluasi fisik pakan komplit berbentuk pellet. J. Teknol. Veteriner. 2009, 480–486. Lestari, G. 2019. Pengaruh penambahan limbah padat tepung tapioka pada feses sapi sebagai substrat biogas terhadap kecernaan nitrogen, konsentrasi vfa, dan total amonia nitogen. Agromedia Berk. Ilm. Ilmu-Ilmu Pertan. 37(1), 1–7. Lestari, E., Muktiani, A. and Harjanti, D. 2020. Kecernaan serat dan total digestible nutrients pakan akibat suplementasi daun katuk, jintan hitam dan mineral dalam rumen sapi perah secara in vitro. Bull. Appl. Anim. Res. 2(2), 67–71. Li, Z., Wu, S., Shen, J., Han, X., Jin, C., Chen, X. and Yao, J. 2020. High rumen degradable starch decreased goat milk fat via trans-10, cis-12 conjugated linoleic acid-mediated downregulation of lipogenesis genes, particularly, INSIG1. J. Anim. Sci. Biotechnol. 11(1), 30. Naytili, G., Yunus, M. and Noach, Y. 2022. Konsumsi, kecernaan bahan kering dan bahan organik cempe jantan peranakan etawah yang diberi suplemen konsentrat mengandung tepung daun katuk dan zn biokompleks. J. Peternak. Lahan Kering. 4(3), 2286. Nimitkeatkai, H., Pasada, K. and Jarerat, A. 2022. Incorporation of tapioca starch and wheat flour on physicochemical properties and sensory attributes of meat-based snacks from beef scraps. Foods 11(7), 1034. Oktarina, E. 2014. Bioremediasi limbah cair tapioka oleh bakteri teramobilisasi pada microbial fuel cell. J. Din. Penelit. Ind. 25(2), 78994. Pancasakti, B., Budhijanto, B. and Vincent, V. 2022. Analisis pengaruh jenis agen crosslinker terhadap karakteristik perekat kayu berbahan tepung tapioka dan pva. J. Sains Teknol. 22(2), 267. Pazla, R., Jamarun, N., Elihasridas, A., Yanti, G. and Ikhlas, Z. 2023. The impact of replacement of concentrates with fermented tithonia (Tithonia diversifolia) and avocado waste (Persea americana miller) in fermented sugarcane tops (Saccharum officinarum) based rations on consumption, digestibility, and production performance of Kacang goat. Adv. Anim. Vet. Sci. 11(3), 394–403. Pazla, R., Jamarun, N., Warly, L., Yanti, G. and Nasution, N.A. 2021a. Lignin content, ligninase enzyme activity and in vitro digestability of sugarcane tops using Pleurotus ostreatus and aspergillus oryzae at different fermentation times. Am. J. Anim. Vet. Sci. 16(3), 192–201. Pazla, R., Jamarun, N., Zain, M., Arief, Yanti, G., Putri, E.M. and Candra, R.H. 2022. Impact of Tithonia diversifolia and Pennisetum purpureum-based ration on nutrient intake, nutrient digestibility and milk yield of Etawa crossbreed dairy goat. Int. J. Vet. Sci. 11(3), 327–335. Pazla, R., Jamarun, N., Zain, M., Yanti, G. and Chandra, R.H. 2021b. Quality evaluation of tithonia (Tithonia diversifolia) with fermentation using Lactobacillus plantarum and Aspergillus ficuum at different incubation times. Biodiversitas J. Biol. Divers. 22(9), 3936–3942. Pazla, R., Yanti, G., Jamarun, N., Zain, M., Triani, H.D., Putri, E.M. and Srifani, A. 2024. Identification of phytase producing bacteria from acidifying Tithonia diversifolia: potential for ruminant feed development. Saudi J. Biol. Sci. 31(7), 104006. Penner, G.B. 2014. Mechanisms of volatile fatty acid absorption and metabolism and maintenance of a stable rumen environment. Proc 25th Fla. Ruminan. Nutr. Symp. 4, 92–104. Pramono, A., Sari, Y., Romadhon, S., Cahyadi, M. and Nugroho, D. 2022. Evaluasi pakan suplemen terproteksi berdasarkan kecernaan bahan kering, kecernaan bahan organik dan ph secara in vitro. Livest. Anim. Res. 20(3), 312. Rahayu, R., Subrata, A. and Achmadi, J. 2018. Fermentabilitas ruminal in vitro pada pakan berbasis jerami padi amoniasi dengan suplementasi tepung bonggol pisang dan molases. J. Peternak. Indones. (Indones. J. Anim. Sci.). 20(3), 166. Rahman, A., Sunarso, S., Tampoebolon, B. and Nuswantara, L. 2020. Pengaruh perbedaan aras starter pada fermentasi sabut kelapa terhadap kecernaan bahan pakan dan produksi volatile fatty acids secara in vitro. J. Ilm. Peternak. Terpadu. 8(2), 66. Rahmawati, P., Pangestu, E., Nuswatara, L. and Christiyanto, M. 2021. Kecernaan bahan kering, bahan organik, lemak kasar dan nilai total digestible nutrient hijauan pakan kambing. J. Agripet. 21(1), 71–77. Retnani, Y., Barkah, N. and Saenab, A. 2020. Processing technology of feed wafer to increase feed production and efficiency. Indones. Bull. Anim. Vet. Sci. 30(1), 37. Riswandi, R., Muhakka, M. and Lehan, M. 2015. Evaluasi nilai kecernaan secara in vitro ransum ternak sapi bali yang disuplementasi dengan probiotik bioplus. J. Peternak. Sriwijaya. 4(1), 35–46. Riswandi, R., Priyanto, L., Imsya, A. and Nopiyanti, M. 2017. Kecernaan in vitro ransum berbasis rumput kumpai (Hymenachne acutigluma) fermentasi disuplementasi legum berbeda (in vitro digestibility of fermented hymenacne acutigluma-based rations supplemented with different legumes). J. Veteriner. 18(2), 303. Rochyani, N., Hasanudin, U., & Syaichurrozi, I. (2022). “Improving Biogas Production in Tapioca Industry by Using Onggok as Co-Substrate.” Int. J. Renew. Energy Res. 13(2), 742–753. Sabri, R., Kasmiran, A. and Fadli, C. 2017. Daya simpan wafer dari bahan baku lokal sebagai bahan pakan ternak ruminansi. J. Eduk. Sains Biol. 6(1), 35–40. Sandi, S., Ali, A.I.M. and Akbar, A.A. 2015. Uji in-vitro wafer ransum komplit dengan bahan perekat yang berbeda. J. Peternak. Sriwijaya 4(2), 35. Silitonga, P., Mirwandhono, R. and Wahyuni, T. 2013. Kecernaan jerami padi yang diolah secara mekanik, kimiawi dan biologi pada pakan domba jantan lokal. J. Peternak. Integr. 1(2), 190–199. Solihin, M. and Sutrisna, R. 2015. The effect of a long storage on water content physical qualities and fungus scatters wafers of vegetables and potatoes waste. J. Ilm. Peternak. Terpadu. 3(2), 48–54. Suharnas, E. 2023. Pengaruh pemanfaatan pod kakao (Theobroma cacao) fermentasi dengan suplementasi mineral, probiotik dan by-pass protein terhadap populasi bakteri rumen secara in-vitro. J. Anim. Res. Appl. Sci. 4(2), 65–70. Sun, X., Harland, R. and Pacheco, D. 2020. Effect of altering ruminal ph by dietary buffer supplementation on methane emissions from sheep fed forage rape. Animal 14(5), 952–962. Suningsih, N., Novianti, S. and Andayani, J. 2017. Level larutan mcdougall dan asal cairan rumen pada teknik in vitro. J. Sain Peternak. Indones. 12(3), 341–352. Sutardi, T., 1991. Pemanfaatan Limbah tanaman perkebunan sebagai pakan ternak ruminansia. Pros. Pem. Prod. Teknol. Peternakan, Fakultas Peternakan IPB , Bogor. Syahri, M., Retnani, Y. and Khotijah, L. 2018. Evaluasi Penambahan Binder Berbeda terhadap Kualitas Fisik Mineral Wafer. Bul. Makanan Ternak. 16(1), 24–35. Tilley, J.M.A. and Terry, D.R. 1963. A two-stage technique for the in vitro digestion of forage crops. Grass Forage Sci. 18(2), 104–111. Trisyulianti, E., Suryahadi. and Rakhma, V.N. 2003. Pengaruh penggunaan molases dan tepung gaplek sebagai bahan perekat terhadap sifat fisik wafer ransum komplit. Media Peternak. 26(2), 35–40. Utomo, R., Budhi, S. and Astuti, I. 2013. Pengaruh level onggok sebagai aditif terhadap kualitas silase isi rumen sapi. Bul. Peternak. 37(3), 173. Van Soest, P.V., Robertson, J.B. and Lewis, B.A. 1991. Methods for dietary fiber, neutral detergent fiber, and nonstarch polysaccharides in relation to animal nutrition. J. Dairy Sci. 74(10), 3583–3597. Vuuren, A., Hindle, V., Klop, A. and Cone, J. 2010. Effect of maize starch concentration in the diet on starch and cell wall digestion in the dairy cow. J. Anim. Physiol. Anim. Nutr. 94(3), 319–329. Wanapat, M., Pilajun, R., Polyorach, S., Cherdthong, A., Khejornsart, P. and Rowlinson, P. 2013. Effect of carbohydrate source and cottonseed meal level in the concentrate on feed intake, nutrient digestibility, rumen fermentation and microbial protein synthesis in swamp buffaloes. Asian-Australas. J. Anim. Sci. 26(7), 952. Wati, E., Suryani, N., and Suryanto, E. (2020). Pengaruh Penambahan molases dan tepung tapioka terhadap kualitas pakan fermentasi jerami padi. J. Ilmu Teknol. Hasil Ternak, 15(2), 123–130 Winarno, F.G. (1992). Kimia Pangan dan Gizi. Jakarta: Gramedia Pustaka Utama. Wong, C.W., Wijayanti, H.B. and Bhandari, B.R. 2015. Maillard reaction in limited moisture and low water activity environment. In Water stress in biological, chemical, pharmaceutical and food systems. Eds., Gutiérrez-López, G.F., Alamilla-Beltrán, L., del Pilar Buera, M., Welti-Chanes, J., Parada-Arias, E. and Barbosa-Cánovas, G.V. New York, NY: Springer, pp: 41–63 Yu, M., Li, Z., Rong, T., Wang, G., Liu, Z., Chen, W. and Ma, X. 2020. Different dietary starch sources alter the carcass traits, meat quality, and the profile of muscle amino acid and fatty acid in finishing pigs. J. Anim. Sci. Biotechnol. 11(1), 78. Zhao, F., Ren, W., Zhang, A., Jiang, N., Liu, W. and Wang, F. 2018. Effects of different amylose to amylopectin ratios on rumen fermentation and development in fattening lambs. Asian-Australas. J. Anim. Sci. 31(10), 1611–1618. | ||

| How to Cite this Article |

| Pubmed Style Jamarun N, Ikhlas Z, Zain M, Negara W, Pazla R, Yanti G. Feed wafers from fermented sugarcane tops and Tithonia diversifolia with added tapioca starch: Effects on physical quality and in-vitro parameters for ruminant feed. Open Vet. J.. 2024; 14(12): 3599-3613. doi:10.5455/OVJ.2024.v14.i12.41 Web Style Jamarun N, Ikhlas Z, Zain M, Negara W, Pazla R, Yanti G. Feed wafers from fermented sugarcane tops and Tithonia diversifolia with added tapioca starch: Effects on physical quality and in-vitro parameters for ruminant feed. https://www.openveterinaryjournal.com/?mno=223819 [Access: January 25, 2026]. doi:10.5455/OVJ.2024.v14.i12.41 AMA (American Medical Association) Style Jamarun N, Ikhlas Z, Zain M, Negara W, Pazla R, Yanti G. Feed wafers from fermented sugarcane tops and Tithonia diversifolia with added tapioca starch: Effects on physical quality and in-vitro parameters for ruminant feed. Open Vet. J.. 2024; 14(12): 3599-3613. doi:10.5455/OVJ.2024.v14.i12.41 Vancouver/ICMJE Style Jamarun N, Ikhlas Z, Zain M, Negara W, Pazla R, Yanti G. Feed wafers from fermented sugarcane tops and Tithonia diversifolia with added tapioca starch: Effects on physical quality and in-vitro parameters for ruminant feed. Open Vet. J.. (2024), [cited January 25, 2026]; 14(12): 3599-3613. doi:10.5455/OVJ.2024.v14.i12.41 Harvard Style Jamarun, N., Ikhlas, . Z., Zain, . M., Negara, . W., Pazla, . R. & Yanti, . G. (2024) Feed wafers from fermented sugarcane tops and Tithonia diversifolia with added tapioca starch: Effects on physical quality and in-vitro parameters for ruminant feed. Open Vet. J., 14 (12), 3599-3613. doi:10.5455/OVJ.2024.v14.i12.41 Turabian Style Jamarun, Novirman, Zaitul Ikhlas, Mardiati Zain, Windu Negara, Roni Pazla, and Gusri Yanti. 2024. Feed wafers from fermented sugarcane tops and Tithonia diversifolia with added tapioca starch: Effects on physical quality and in-vitro parameters for ruminant feed. Open Veterinary Journal, 14 (12), 3599-3613. doi:10.5455/OVJ.2024.v14.i12.41 Chicago Style Jamarun, Novirman, Zaitul Ikhlas, Mardiati Zain, Windu Negara, Roni Pazla, and Gusri Yanti. "Feed wafers from fermented sugarcane tops and Tithonia diversifolia with added tapioca starch: Effects on physical quality and in-vitro parameters for ruminant feed." Open Veterinary Journal 14 (2024), 3599-3613. doi:10.5455/OVJ.2024.v14.i12.41 MLA (The Modern Language Association) Style Jamarun, Novirman, Zaitul Ikhlas, Mardiati Zain, Windu Negara, Roni Pazla, and Gusri Yanti. "Feed wafers from fermented sugarcane tops and Tithonia diversifolia with added tapioca starch: Effects on physical quality and in-vitro parameters for ruminant feed." Open Veterinary Journal 14.12 (2024), 3599-3613. Print. doi:10.5455/OVJ.2024.v14.i12.41 APA (American Psychological Association) Style Jamarun, N., Ikhlas, . Z., Zain, . M., Negara, . W., Pazla, . R. & Yanti, . G. (2024) Feed wafers from fermented sugarcane tops and Tithonia diversifolia with added tapioca starch: Effects on physical quality and in-vitro parameters for ruminant feed. Open Veterinary Journal, 14 (12), 3599-3613. doi:10.5455/OVJ.2024.v14.i12.41 |