| Original Article | ||

Open Vet J. 2021; 11(3): 356-363 Open Veterinary Journal, (2021), Vol. 11(3): 356–363 Original Research Fundamental role of Lactobacillus plantarum and inulin in improving safety and quality of Karish cheeseOla W. Hegab*, Eman F. Abdel-Latif, Hamdy M.B.A. Zaki and Ashraf A. MoawadDepartment of Food Hygiene and Control, Faculty of Veterinary Medicine, Cairo University, Giza, Egypt *Corresponding Author: Ola Wagih Hegab. Department of Food Hygiene and Control, Faculty of Veterinary Medicine, Cairo University, Giza, Egypt. Email: olawagihvet90 [at] gmail.com Submitted: 27/02/2021 Accepted: 27/06/2021 Published: 19/07/2021 © 2021 Open Veterinary Journal

AbstractBackground: Karish cheese manufactured traditionally from raw milk may harbor many biological health hazards. Aim: Production of safe pasteurized Karish cheese with improved sensory characteristics using probiotics and prebiotics (synbiotic Karish cheese). Methods: Laboratory Karish cheese was made to study the effect of Lactobacillus plantarum with and without inulin on cheese quality. Treatments were examined for sensory, chemical, and microbial quality, shelf life, and survival of L. plantarum were also monitored. The antimicrobial effect of L. plantarum and inulin against Enterobacter aerogenes in cheese was evaluated. Results: Sensory, chemical, and microbial quality of Karish cheese supplemented with L. plantarum and inulin were positively affected; moreover, the shelf life was extended up to 28 days. Karish cheese contained L. plantarum showed the highest flavor score, while treatment contained both L. plantarum and inulin attained the best body and texture score. Moreover, L. plantarum and inulin significantly reduced E. aerogenes count during Karish cheese chilled storage; the reduction log reached 3.76 log10cfu/g on the seventh day of storage compared to control. Additionally, Inulin significantly increased the survival of L. plantarum throughout the storage period. Conclusion: This study concluded that using probiotics and prebiotics in Karish cheese synergistically improved its sensory properties, safety, and hygienic quality. Keywords: Enterobacter aerogens, inulin, Karish cheese, Lactobacillus plantarum, synbiotic. IntroductionRecently, consuming low-fat foods includes cheeses to reduce health risks associated with high dietary fats as heart diseases, hypertension, arteriosclerosis, and obesity (Tufeanu and Tiţa, 2016). Karish cheese is one of the most popular white soft skimmed milk cheeses manufactured traditionally in Egyptian villages from the raw milk. In the traditional method, raw milk is kept in earthenware pots for 24–72 hours (differs according to the season) until the cream layer is separated, then it is removed, and the remaining fermented skim milk pressed and transferred into a mat that hanged for 2–3 days to drain whey after that it is dry salted, cut into cubes, and left to drain for 2 hours before consumption (Hammam et al., 2020). Traditional Karish cheese produced from the raw milk under poor hygienic measures may contain several health risk contaminants (Hamad, 2015). Industrially produced Karish cheese is manufactured using pasteurized skim milk having 0.1%–0.5% fat content relaying on the quality of the separator, with the addition of starter culture (Todaro et al., 2013; Allam et al., 2017a). Consumers usually prefer traditional Karish cheese owing to its good flavor created by native microflora of raw milk (Hegab et al., 2020). Additionally it contains a relatively higher fat content compared to industrial one due to different fat separation methods. It is worth mentioning that the fat acts as a flavor enhancer for cheese and gives it a characteristic texture, fat removal leading to lack of good cheese flavor and rubbery texture (Madadlou et al., 2005; Awad, 2016). The challenge is to produce a safe pasteurized Karish cheese more closely resembles the conventional one in its organoleptic properties and solve fat removal problems. Several trials have been proposed to improve Karish cheese, using probiotics and prebiotics to adjust its organoleptic properties and provide it with health-promoting benefits (Ahmed et al., 2005; Hamad, 2015). Functional synbiotic products are considered as the modern trend in food technology that containing both probiotics and prebiotics (Angiolillo et al., 2014a). Probiotics are live microorganisms that are used widely in many foodstuffs, including dairy products. They deliver many health benefits to humans when they exist in food at the time of consumption with a minimum count of 7.0 log10cfu/g. Probiotics contribute to the re-balance of beneficial intestinal microflora and inhibit harmful entero-pathogens that improve digestive ability and relieve constipation. In addition, probiotics decrease the blood cholesterol level, improve body immunity, and have antimutagenic and anticarcinogenic effects (Hammam and Ahmed, 2019; Ali et al., 2020). Probiotics also play a technological role in food, particularly dairy products; they act as bio-preservatives, prolong the shelf life of fresh dairy products, and improve their sensory characteristics (Angiolillo et al., 2014b; Allam et al., 2017a). Generally, cheeses are considered as better vehicles for carrying probiotics than others dairy products due to their higher pH and more solid consistency that protect probiotics in the human intestine (Modzelewska-Kapituła et al, 2007; Hussein and Shalaby, 2014). Lactobacillus plantarum is one of the most protective and health-promoting Lactic acid bacteria (LAB). It is known to produce antimicrobial substances, e.g., plantaricin, that inhibit many pathogenic and spoilage microorganisms, for example, Escherichia coli, Salmonella Typhimurium, Staphylococcus aureus, Enterobacter aerogenes, Proteus vulgaris, and Pseudomonas aeruginosa (Dinev et al., 2018; Al-Gamal et al., 2019). Meanwhile, the L. plantarum DSM 20174 strain is a promising strain with many probiotic properties, which help exhibit its beneficial effects inside the human body. These probiotic properties including tolerance to acid and bile salts, resistance to many antibiotics, and production of β galactosidase enzyme that helps in lactose digestion. Moreover, it can ferment fructooligosaccharides used in synbiotic products (Cebeci and Gürakan, 2003). The same L. plantarum DSM 20174 strain was used in the current study. Enterobacter aerogenes is an opportunistic bacterium that has emerged as a nosocomial pathogen as well as a spoilage microorganism. It is a member of the coliform group that characterized by acid and gas production from lactose, result in undesirable flavors, slime formation, and discoloration in dairy products; it is often isolated from raw milk and Karish cheese (Baylis, 2006; Davin-Regli and Pagès, 2015; Dinev et al., 2018). Prebiotics are non-digestible carbohydrates metabolized selectively by probiotic bacteria in the large intestine, stimulating the growth of beneficial bacteria and improving gut health (Karimi et al., 2015). Inulin is one of the best prebiotics used in foods, especially in dairy products; it is a carbohydrate polymer consisting of fructose units, soluble dietary fiber, and generally regarded as a safe food ingredient. It is added in dairy products within an average of 2%–10%, not only to give a good viable count of probiotics during the storage period but also acts as a fat replacer and flavor enhancer (Modzelewska-Kapituła et al., 2007; Karimi et al., 2015; Junyusen et al., 2017). This study aims to produce a synbiotic Karish cheese using L. plantarum in addition to inulin to detect their influence on its sensory, chemical, microbial quality, and shelf life. Moreover, studying the antimicrobial effect of L. plantarum and inulin on the survival of E. aerogenes, as well as investigating the effect of inulin on the viability of L. plantarum in cheese during the storage period. Materials and MethodsMaterialsFresh buffalo’s skim milk was obtained from the Faculty of Agriculture, Cairo University. Chemical parameters of the used milk were determined using a milk analyzer (LCD display- 4 lines × 16 characters, 100-240V-1.6A max., Bulgaria); Commercial starter culture was purchased from Chr. Hansen (White Daily 41) Freeze Dried- Direct Vat Set (FD-DVS) contained Lactobacillus delbrueckii ssp. Bulgaricus, Lactococcus lactis ssp. Lactis, Lactococcus lactis ssp. Cremoris, and Streptococcus thermophilus. Strains of L. plantarum DSM 20174 and E. aerogenes DSM 30053 were obtained from Cairo-MIRCEN, Faculty of Agriculture, Ain-Shams University. Food grade fine salt from El-Nasr Salines Company, Egypt. Calcium chloride from Sigma Chemical Company, Str. Louis, USA. Microbial rennet powder (Reniplus 2000 IMCU) from Caglio Star, Proquiga, Spain) and Inulin (Orafti®, Belgium) were used. Strains preparationLactobacillus plantarum was cultivated in MRS broth for 24 hours/37°C then enriched in sterile skimmed milk for 24 hours/37°C to reach approximately 9 log10cfu/g that was determined by plating serial dilutions on De Man, Rogosa, and Sharpe agar (MRS agar HIMEDIA). Enterobacter aerogenes was activated in tryptic soy broth (TSB) and incubated at 37°C/24 hours to reach a final concentration of approximately 8 log10cfu/g which was counted by plating serial dilutions on MacConkey agar (Oxoid) supplemented with 50 μg /ml nalidixic acid. Karish cheese preparationKarish cheese was manufactured as follows: the fresh milk was laboratory pasteurized at 74oC/15 seconds then suddenly cooled. Starter culture, rennet, and calcium chloride were added at 37°C according to the manufacturer instructions. The milk was left till coagulation (40–45 minutes), then the curd was scooped into mats similar to those used in the traditional technology to be like the shape of traditional cheese. Dry salt (2.5 g/100 g cheese) was sprinkled on the surface of the curd and left to drain. The resultant cheese was cut and packed in airtight plastic containers containing salted whey (2.5% salt) then stored at 4oC (Ahmed et al., 2005). Experimental designPart 1: study the effect of using L. plantarum with and without inulin on Karish cheese quality Three separate Karish cheese treatments were made: control (C) treatment that prepared exactly like the previously mentioned steps in cheese preparation, (P) treatment prepared as control with inoculation of L. plantarum at a ratio of (2%, v/v), and (PI) treatment was done as control with the addition of both L. plantarum and 4% inulin. Samples were examined at zero, 3, 7, 14, 21, 28, and 35 days or till the appearance of spoilage sign(s) to determine the sensory, chemical, microbial quality, and shelf life of prepared cheeses. The experiments were done in triplicate. Sensory evaluationSensory evaluation was carried out according to the American Dairy Science Association scorecard scheme described by Bodyfelt and Potter (2009) in which sensory panelists were asked to provide an evaluation score as following: flavor (1–10 points, where 1=extremely undesirable and 10=excellent), body and texture (1–5 points, where 1=extremely undesirable and 5=excellent), and color and appearance (1–5 points, where 1=extremely undesirable and 5=excellent). The overall grade (20) was calculated from (100), (20=100%). Ten experienced panelists (from both sexes in the age range of 25–55 years) were chosen from the Food Hygiene and Control department staff members at the Faculty of Veterinary Medicine, Cairo University, Egypt. The prepared Karish cheese samples were cut, placed on white plates, and presented to the panelists randomly. Water was provided for mouth washing between samples. Chemical analysisTitratable acidity and moisture % were done according to guidelines of the Association of Official Analytical Chemists (AOAC, 2000). Microbiological analysisPresumptive coliform, staphylococci, yeast, and mold counts according to the guidelines of the American Public Health Association (APHA, 2004). Furthermore, the survival of L. plantarum was investigated. Part 2: study the antimicrobial effect of L. plantarum with and without inulin on the survival of E. aerogenes in Karish cheese Three separate Karish cheese treatments were made: control treatment that inoculated with E. aerogenes (CE). The second was (PE) treatment which contained (E. aerogenes + L. plantarum). The third was (PIE) treatment that contained (E. aerogenes + L. plantarum + 4% inulin). Samples were examined at 0, 3, 7, 14, and 21 days or till the appearance of spoilage sign (s) to determine the survival of E. aerogenes and L. plantarum as well as chemical parameters were measured. The experiments were carried out in triplicate. Statistical analysisAll measurements were carried in triplicates; the results were expressed as mean ± standard error (SE). Data were also statistically analyzed by Analysis of variance using SPSS 23 for windows. Multiple comparisons of means were made using the least significant difference at the significance level (p < 0.05). Ethical approvalIn this study, we did not use any experimental live animals. ResultsChemical analysis of buffalo milk used in the current studyThe compositional analysis of used buffalo milk in this study was as following: fat (0.15%), S.N.F (9.39%), protein (3.48%), lactose (5%), titratable acidity (0.16%), and (pH 6.6.) Part 1: effect of using L. plantarum with and without inulin on Karish cheese qualitySensory evaluation Data presented in Table 1 shows that all sensorial attributes were significantly higher in (P) and (PI) treatments than in control. The highest mean flavor was recorded on the third day in (P) treatment (10) followed by (PI) treatment (9.8) as compared to (C) treatment (7.7). Regarding body and texture, color, and appearance scores, (PI) treatment was the uppermost (5), followed by (P) treatment (4.8) on the third day of examination. The highest overall score for (PI) and (P) treatments was recorded on the third day; it was not significantly different, 98.7 and 98.3, respectively, but significantly different from control 75.8. Table 1. Sensory evaluation of Karish cheese treatments (Mean ± SE).

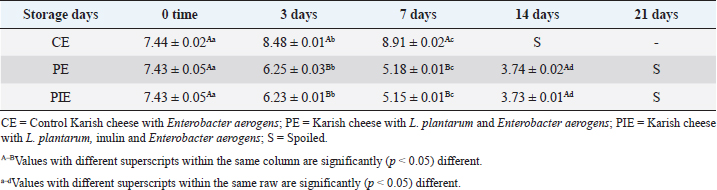

Microbiological analysisPresumptive coliform, staphylococci, yeast, and mold counts were not detected (<10 cfu/g) over the entire storage time except yeast appears in (C) treatment at day 21 with mean 1.60 log10cfu/g. Part 2: The antimicrobial effect of L. plantarum with and without inulin on the survival of E. aerogenes in Karish cheese treatmentsData presented in Table 2 reveals that there was a significant reduction in E. aerogenes count started from third day in (PIE) (6.23 log10cfu/g) and (PE) (6.25 log10cfu/g) treatments compared to (CE) treatment (8.48 log10cfu/g). The log reduction rate reached to 3.76 log10cfu/g on the seventh day of storage in (PIE) compared to (CE) treatment. E. aerogenes count is significantly decreased in PIE and PE treatments throughout the storage period till it reached (3.73 log10cfu/g) in (PIE) treatment and (3.74 log10cfu/g) in (PE) treatment at 21 days. Effect of using inulin on the survival of L. plantarum during storage period in different Karish cheese treatmentsAs seen in Table 3, the addition of inulin significantly increase L. plantarum count in (PI) treatment (9.69 log10cfu/g) compared to (P) treatment without inulin (9 log10cfu/g) started on the third day and till the end of the storage period. Chemical analysis of different Karish cheese treatmentsThere was a significant increase in acidity % in all Karish cheese treatments (Table 4) within the storage period, the lowest acidity % obtained at zero time in (C) treatment (0.30), while the highest was obtained at 14 days in (PIE) treatment (1.03). The highest moisture content was obtained in treatments with 4% inulin (PI) (72.5) and (PIE) (72.3) at zero time till the end of the storage period compared to other treatments. DiscussionPart 1: effect of using L. plantarum with and without inulin on Karish cheese qualitySensory evaluation Data presented in Table 1 illustrats the impact of using L. plantarum alone or with 4% inulin on the organoleptic properties of Karish cheese. Flavor scores of (P) and (PI) treatments were significantly higher than (C) treatment throughout the storage period. Graders described the flavor of (P) treatment as excellent. The addition of lactobacilli as L. plantarum into cheese can significantly influence cheese proteolysis that is carried out through hydrolysis of caseins into peptides by milk enzymes, rennet, starter culture, and probiotic enzymes. Furthermore, the formed peptides are extra hydrolyzed by probiotic enzymes into smaller peptides and free amino acids that play a principal role in developing cheese flavor and texture (Karimi et al., 2012). Results agreed with those obtained by El-Shafei et al. (2008) and Allam et al. (2017a). Unlike other fat replacers, inulin can form a stable creamy-like gel without negatively affecting cheese flavor (Karimi et al., 2015). The current results were in accordance with Arcia et al. (2011) and Modzelewska-Kapituła et al. (2007), who reported that inulin improves cheese’s sensorial properties, especially flavor. However, Franck (2002), Giri et al. (2017) found that the typical flavor of cheese decrease with increasing the amount of inulin as it gives a sweet taste affects cheese flavor. Table 2. Survival of Enterobacter aerogens in different Karish cheese treatments (log10 Mean ± SE).

Table 3. Survival of L. plantarum in different Karish cheese treatments (log10 Mean ± SE).

Table 4. Chemical examination of Karish cheese treatments (Mean ± SE).

Concerning body and texture, color, and appearance scores, (PI) treatment was the uppermost, followed by (P) treatment as demonstrated in Table 1. Inulin effectively achieves textural adjustment through acting as a bulking and texturizing agent (Tufeanu and Tița, 2016; Junyusen et al., 2017). The softening effect of inulin could be attributed to its higher affinity to absorb moisture (Koca and Metin, 2004; Karimi et al., 2015). Inulin results agreed with those obtained by Alnemr et al. (2013) in Karish cheese and with Salvatore et al. (2014) and Junyusen et al. (2017) in reduced-fat fresh cheese. Furthermore, Da Cruz et al. (2009) and Tufeanu and Tița (2016) reported that inulin and Lactobacillus improved the organoleptic profile of reduced-fat-cheeses. Additionally, Abou Ayana and Ibrahim (2015) reported that LAB improved the texture of Karish cheese. The overall grade results of (P) and (PI) treatment reflected the success of L. platarum and inulin 4% in enhancing the organoleptic characteristics of Karish cheese, nearly similar to the conventional cheese made by farmers but with higher hygienic quality and capable of delivering specific health benefits. Microbiological analysis and shelf lifePresumptive coliform, staphylococci, yeast, and mold counts were not detected (<10 cfu/g) over the entire storage time except yeast appears in (C) treatment at day 21 with mean 1.60 log10cfu/g; however, these results were within the acceptable limit of Egyptian standards (2005) (Not exceed 2.6 log10cfu/g). Heat treatment of cheese milk and using L. plantarum and inulin improved the hygienic quality of Karish cheese. Those results were in harmony with those obtained by Lavermicocca et al. (2000), El-Shafei et al. (2008), Allam et al. (2017b), and Ali et al. (2020). In regards to shelf life, Karish cheeses prepared using L. plantarum (P) recorded the highest shelf life (28) days followed by PI treatment (21 days), while (C) treatment was the lowest (14) days. The obtained results reflected the ability of L. plantarum to prolong the shelf life of Karish cheese, which usually ranges from 1 to 2 weeks (Hammam et al., 2020). This prolonged shelf life is owed to the ability of L. plantarum to produce bacteriocins, hydrogen peroxide, and organic acids, which hinder spoilage microbial growth (Dinev et al., 2018). Part 2: The antimicrobial effect of L. plantarum with and without inulin on the survival of E. aerogenes in Karish cheese treatmentsThere was a significant reduction in E. aerogenes count in (PIE) and (PE) started from the third day then decreased significantly (p < 0.05) during the storage period (Table 2). Using Lactobacilli as an alternative to chemical preservatives has acquired much attention nowadays (Gupta and Srivastava, 2014; Shekh et al., 2016; Dinev et al., 2018). Several researchers reported the unique antimicrobial characters of L. plantarum against broad-spectrum Gram-positive and Gram-negative bacteria. It can produce bacteriocins, hydrogen peroxide, and organic acids (Dinev et al., 2018). The current results in accordance with those of Tambekar and Bhutada (2010), Shekh et al. (2016), Al-Gamal et al. (2019), Ali et al. (2020), and Vataščinová et al. (2020), who confirmed that L. plantarum had displayed antibacterial activity against E. aerogenes, E. coli, Salmonella enteritidis, Pseudomonas aeruginosa, Listeria monocytogenes, Listeria ivanovii, S. aureus, Bacillus cereus, and Candida albicans. Effect of using inulin on the Survival of L. plantarum during the storage periodThe addition of inulin (4%) significantly increases L. plantarum count in (PI) treatment compared to (P) treatment without inulin throughout the chilled storage period. The growth rate of L. plantarum increased during the storage of Karish cheese. It decreased gradually until the end of the storage period; this reduction may be related to intensive lactic acid production and refrigerated storage temperature (Karimi et al., 2015). However, it survived well in all inoculated treatments at the recommended level of 7.0 log10cfu/g, which required probiotics to deliver its benefits to humans (Hammam and Ahmed, 2019). Those results were in parallel with those found by Modzelewska-Kapituła et al. (2007). Chemical evaluation of Karish cheese treatmentsThe highlighted results in Table 4 including that there was a significant development in acidity % in all treatments during storage days, a slight significant (p < 0.05) increase in treatments containing L. plantarum, and E. aerogenes within storage time due to acid production from both bacteria. Rapid gas and acid production from lactose fermentation is considered a diagnostic feature of E. aerogenes (Baylis, 2006). Regarding moisture %, it was significantly affected when using inulin in (PI) and (PIE) treatments owing to water absorbability of inulin and consequent increase in the moisture content. The finding is consistent with the experiments of Alnemr et al. (2013) in Karish cheese and Juan et al. (2013) in reduced-fat fresh cheese. ConclusionOutcomes of this study clarified that the addition of L. plantarum and inulin into Karish cheese synergistically enhanced its sensory characteristics, hygienic quality, and shelf life. Moreover, the addition of inulin positively affects the viability of L. plantarum. This study recommended using L. plantarum and inulin in pasteurized Kaish cheese to produce a safe product nearly similar to the traditional one with new functional synbiotic properties. Conflict of interestThe Authors declare that there is no conflict of interest. Author’s contributionAshraf A. Moawad planned, supervised the study, and revised the final version of manuscript before submission. Eman F. Abdel-Latif shared in the study design, assisted in experiment performing, and reviewed the final manuscript. Hamdy M.B.A. Zaki and Ola W. Hegab collected the required materials, performed different experimental treatments, collect the data, interpreted and statically analyzed the obtained results, finally they drafted the manuscript. ReferencesAbou Ayana, I.A.A. and Ibrahim, A.E. 2015. Attributes of low fat Yogurt and Kareish cheese made using exopolysaccride producing lactic acid bacteria. Am. J. Food Technol. 10, 48–57. Ahmed, N.H., El Soda, M., Hassan, A.N. and Frank, J. 2005. Improving the textural properties of an acid-coagulated (Karish) cheese using exopolysaccharide producing cultures. LWT-Food Sci. Technol. 38, 843–847. Al-Gamal, M.S., Ibrahim, G.A., Sharaf, O.M., Radwan, A.A., Dabiza, N.M., Youssef, A.M. and El-ssayad, M.F. 2019. The protective potential of selected lactic acid bacteria against the most common contaminants in various types of cheese in Egypt. Heliyon. 5, e01362. Ali, F.S., Zayed, G., Saad, O.A.O. and Gharib, S.A.H. 2020. Antimicrobial activity and probiotic properties of lactic acid bacteria isolated from traditional fermented dairy products. J. Mod. Res. 2, 40-48. Allam, M.G., Darwish, A.M., Ayad, E.H.E., Shokery, E.S. and Darwish, S.M. 2017b. Lactococcus species for conventional Karish cheese conservation. LWT-Food Sci. Technol. 79, 625–631. Allam, M.G., Darwish, A.M.G. and Ayad, E.H.E. 2017a. Improve hygienic quality of Egyptian Karish cheese employing isolated antagonistic lactobacilli strains. Annu. Res. Rev. Biol. 19, 1–13. Alnemr, T.M., Abd El-RazeK, A.M., Hasan, H.M.A. and Massoud, M.I. 2013. Improving of Karish cheese by using enhanced technological texturizing inulin, Alex. J. Agric. Res. 58, 173–181. Angiolillo, L., Conte, A., Faccia, M., Zambrini, A.V. and Del Nobile, M.A. 2014a. A new method to produce synbiotic Fiordilatte cheese. Innov. Food Sci. Emerg. Technol. 22, 180–187. Angiolillo, L., Conte, A., Faccia, M., Zambrini, A.V. and Del Nobile, M.A. 2014b. Biopreservation of Fior di Latte cheese. J. Dairy Sci. 97, 5345–5355. AOAC. 2000. Official methods of analysis of AOAC International, 17th ed. Gaithersburg, MD: AOAC International. APHA. 2004. Standard Methods for Examination of Dairy Products, 17th ed. Washington, DC: American Public Health Association. Arcia, P.L., Navarro, S., Costell, E. and Tarrega, A. 2011. Effect of inulin seeding on rheology and microstructure of prebiotic dairy desserts. Food Biophys. 6, 440–449. Awad, S. 2016. Microbial safety criteria and quality of traditional Egyptian Karish cheese. Afr. J. Microbiol. Res. 10, 804–812. Baylis, C.L. 2006. Part V spoilage bacteria, 22- enterobacteriaceae. In Food spoilage microorganisms, Eds., Blackburn, C.W. Sawston, UK: Woodhead Publishing Ltd, pp: 624–659. Bodyfelt, F. and Potter, D. 2009. Creamed cottage cheese. In The sensory evaluation of dairy products, 2nd ed. Eds., Clark, S., Costello, M., Drake, M. and Bodyfelt, F., New York, NY, Springer Science Business Media, LLC, pp: 167–190. Cebeci, A. and Gürakan, C. 2003. Properties of potential probiotic Lactobacillus plantarum strains. Food Microbiol. 20, 511–518. Da Cruz, A.G., Buriti, F.C.A., de Souza, C.H.B., Faria, J.A.F. and Saad, S.M.I. 2009. Probiotic cheese: health benefits, technological and stability aspects. Trends Food Sci. Technol. 20, 344–354. Davin-Regli and Pagès, A.J. 2015. E. aerogenes and Enterobacter cloacae; versatile bacterial pathogens confronting antibiotic treatment. Front. Microbiol. 6, 1–10. Dinev, T., Beev, G., Tzanova, M., Denev, S., Dermendzhieva, D. and Stoyanova, A. 2018. Antimicrobial activity of Lactobacillus plantarum against pathogenic and food spoilage microorganisms: a review. Bulg. J. Vet. Med. 21, 253–268. Egyptian Standards. 2005. Karish cheese. E. S. 1008 4/2005. In Egyptian Organization for Standardization and Quality Control. Karish cheese, Egypt: Ministry of industry and technological development. El-Shafei, K., Abd El-Gawad, M.A.M., Dabiza, N., Sharaf, O.M. and Effat, B.A. 2008. A mixed culture of propionibacterium thoenii p-127, lactobacillus rhamnosus and Lactobacillus plantarum as protective cultures in Kareish cheese. Polish J. Food Nutr. Sci. 58, 433–441. Franck, A. 2002. Technological functionality of inulin and oligofructose. Br. J. Nutr. 87, 287–291. Giri, A., Kanawjia, S.K. and Singh, M.P. 2017. Effect of inulin on physico-chemical, sensory, fatty acid profile and microstructure of processed cheese spread. J. Food Sci. Technol. 54, 2443–2451. Gupta, R. and Srivastava, S. 2014. Antifungal effect of antimicrobial peptides (AMPs LR14) derived from Lactobacillus plantarum strain LR/14 and their applications in prevention of grain spoilage. Food Microbiol. 42, 1-7. Hamad, M.N.F. 2015. Effect of adding glucono-δ-lactone, different of starters, rennet on the chemical composition, yield and economic study of Kareish cheese. Int. J. Food Sci. Nutr. 5, 130–140. Hammam, A.R., Elfaruk, M.S., Ahmed, M.E. and Sunkesula, V. 2020. Characteristics and technological aspects of the Egyptian cheeses. Int. J. Curr. Microbiol. Appl. Sci. 9, 3338–3354. Hammam, A.R.A, and Ahmed, M.S.I. 2019. Technological aspects, health benefits, and sensory properties of probiotic cheese. SN Appl. Sci. 1, 1–9. Hegab, O.W., Abdel-Latif, E.F. and Moawad, A.A. 2020. Isolation of enterotoxigenic Staphylococcus aureus harboring seb gene and enteropathogenic Escherichia coli (serogroups O18, O114, and O125) from soft and hard artisanal cheeses in Egypt. Open Vet. J. 10, 297–307. Hussein, G.A.M. and Shalaby, S.M. 2014. Microstructure and textural properties of Kareish cheese manufactured by various ways. Ann. Agric. Sci. 59, 25–31. Juan, B., Zamora, A., Quintana, F., Guamis, B., and Trujillo, A.J. 2013. Effect of inulin addition on the sensorial properties of reduced-fat fresh cheese. Int. J. Dairy Technol. 66, 478–483. Junyusen, T., Ngampang, N., Sangmuang, A., Suthada, S. and Chatchavanthatri, N. 2017. The effects of inulin on the textural, thermal, and microstructural properties of reduced-fat cheese. Suranaree J. Sci. Technol. 24, 23–30. Karimi, R., Azizi, M.H., Ghasemlou, M. and Vaziri, M. 2015. Application of inulin in cheese as prebiotic, fat replacer and texturizer: a review. Carbohydr. Polym. 119, 85–100. Karimi, R., Sohrabvandi, S. and Mortazavian, A.M. 2012. Review article: sensory characteristics of probiotic cheese. Compr. Rev. Food Sci. Food Saf. 11, 437–752. Koca, N. and Metin, M. 2004. Textural, melting and sensory properties of low-fat fresh Kashar cheeses produced by using fat replacers. Int. Dairy J. 14, 365–373. Lavermicocca, P., Valerio, F., Evidente, A., Lazzaroni, S., Ccorsetti, A. and Gobbetti, M. 2000. Purification and characterization of novel antifungal compounds from the sourdough Lactobacillus plantarum strains 21B. Appl. Environ. Microbiol. 66, 4084–4090. Madadlou, A., Khosroshahi, A. and Mousavi, M.E. 2005. Rheology, microstructure, and functionality of low-fat Iranian white cheese made with different concentrations of rennet. J. Dairy Sci. 88, 3052–3062. Modzelewska-Kapituła, M., Kłębukowska, L., and Kornacki, K. 2007. Influence of inulin and potentially probiotic Lactobacillus plantarum strain on microbiological quality and sensory properties of soft cheese. Polish J. Food Nutr. Sci. 57, 143–146. Salvatore, E., Pes, M., Mazzarello, V. and Pirisi, A. 2014. Replacement of fat with long-chain inulin in a fresh cheese made from caprine milk. Int. Dairy J. 34, 1–5. Shekh, S.L., Dave, J.M. and Vyas, B.R.M. 2016. Characterization of Lactobacillus plantarum strains for functionality, safety and γ-amino butyric acid production. LWT-Food Sci. Technol. 74, 234–241. Tambekar, D.H. and Bhutada, S.A. 2010. Acid and bile tolerance, antibacterial activity, antibiotic resistance and bacteriocins activity of probiotic lactobacillus species. Recent res. Sci. Technol. 2, 94–98. Todaro, A., Adly, F.A. and Omar, O.A.H. 2013. History, processing and quality enhancement of traditional Egyptian Kariesh Cheese: a review. Food Sci. technol. 1, 1–6. Tufeanu, R. and Tiţa, O. 2016. Possibilities to develop low-fat products: a review. Acta Univ. Cibiniensis, Ser. E: Food Technol. 20, 3–19. Vataščinová, T., Pipová, M., Fraqueza, M.J.R., Maľa, P., Dudriková, E., Drážovská, M. and Lauková, A. 2020. Antimicrobial potential of Lactobacillus plantarum strains isolated from Slovak raw sheep milk cheeses. J. Dairy Sci. 103, 6900–6903. | ||

| How to Cite this Article |

| Pubmed Style Hegab OW, Abdel-Latif EF, HMZ, Moawad AA, . Fundamental role of Lactobacillus plantarum and inulin in improving safety and quality of Karish cheese. Open Vet J. 2021; 11(3): 356-363. doi:10.5455/OVJ.2021.v11.i3.4 Web Style Hegab OW, Abdel-Latif EF, HMZ, Moawad AA, . Fundamental role of Lactobacillus plantarum and inulin in improving safety and quality of Karish cheese. https://www.openveterinaryjournal.com/?mno=59695 [Access: July 27, 2024]. doi:10.5455/OVJ.2021.v11.i3.4 AMA (American Medical Association) Style Hegab OW, Abdel-Latif EF, HMZ, Moawad AA, . Fundamental role of Lactobacillus plantarum and inulin in improving safety and quality of Karish cheese. Open Vet J. 2021; 11(3): 356-363. doi:10.5455/OVJ.2021.v11.i3.4 Vancouver/ICMJE Style Hegab OW, Abdel-Latif EF, HMZ, Moawad AA, . Fundamental role of Lactobacillus plantarum and inulin in improving safety and quality of Karish cheese. Open Vet J. (2021), [cited July 27, 2024]; 11(3): 356-363. doi:10.5455/OVJ.2021.v11.i3.4 Harvard Style Hegab, O. W., Abdel-Latif, E. F., , H. M. Z., Moawad, A. A. & (2021) Fundamental role of Lactobacillus plantarum and inulin in improving safety and quality of Karish cheese. Open Vet J, 11 (3), 356-363. doi:10.5455/OVJ.2021.v11.i3.4 Turabian Style Hegab, Ola Wagih, Eman F. Abdel-Latif, Hamdy M.B.A. Zaki, Ashraf A. Moawad, and . 2021. Fundamental role of Lactobacillus plantarum and inulin in improving safety and quality of Karish cheese. Open Veterinary Journal, 11 (3), 356-363. doi:10.5455/OVJ.2021.v11.i3.4 Chicago Style Hegab, Ola Wagih, Eman F. Abdel-Latif, Hamdy M.B.A. Zaki, Ashraf A. Moawad, and . "Fundamental role of Lactobacillus plantarum and inulin in improving safety and quality of Karish cheese." Open Veterinary Journal 11 (2021), 356-363. doi:10.5455/OVJ.2021.v11.i3.4 MLA (The Modern Language Association) Style Hegab, Ola Wagih, Eman F. Abdel-Latif, Hamdy M.B.A. Zaki, Ashraf A. Moawad, and . "Fundamental role of Lactobacillus plantarum and inulin in improving safety and quality of Karish cheese." Open Veterinary Journal 11.3 (2021), 356-363. Print. doi:10.5455/OVJ.2021.v11.i3.4 APA (American Psychological Association) Style Hegab, O. W., Abdel-Latif, E. F., , H. M. Z., Moawad, A. A. & (2021) Fundamental role of Lactobacillus plantarum and inulin in improving safety and quality of Karish cheese. Open Veterinary Journal, 11 (3), 356-363. doi:10.5455/OVJ.2021.v11.i3.4 |